Needle Punched Nonwoven Fabric For Soil Stabilization

- Packaging:

- woven bag or as customers' requests

- Productivity:

- 1000000 square meter

- Brand:

- BOYA

- Transportation:

- Ocean,Land,Air

- Place of Origin:

- China

- Supply Ability:

- 10000 square meter per week

- Certificate:

- ISO9001:2000 ISO14001:2000

- Port:

- Ningbo Port,Shanghai Port,Shenzhen Port

Basic Info

Model No.: Geotextile

Product Description

Needle Punched Nonwoven Fabric For Soil Stabilization

Needle punched geotextile is made of polypropylene stable fibers. This needle punched nonwoven fabric comes in a variety of densities and provides excellent physical and hydraulic properties in order to high tensile strengths. Felted geotextiles often used as underlayment for rock traffic surfaces, soil stabilization, or use in water filtering systems where slow flow or combined materials.

Product features:

This product has the function of filtering, isolation, strengthening, high tensile strength, good permeability, high temperature resistance, freezing resistance, ageing resistance and corrosion resistance.

Four basic functions are defined for the geotextile:

Filtration

Filtration functions to restrict the migration of fine soil particles from a soil mass while remaining permeable to water movement greater than, or at least equivalent to the permeability of the protected soil.

Drainage

Water is conveyed along the path of the geotextile due to its construction, and then to an outlet. Water may be vertically or horizontally conveyed. Drainage is related to the role of filtration, and is a function of the permeability of a geotextile and its pore opening size or porometry.

Separation

Separation is the function which prevents two distinct soils of different materials from intermixing. The key factors for a geotextile to satisfy this function are porometry, toughness and strength.

Reinforcement

This function involves the stabilization of a soil mass by provision of tensile strength to the soil-fabric system.

Geotextile selection can be expressed as a relationship between these 4 basic functions and the properties required by the design engineer in order to satisfy certain criteria, which would relate to a specific application.

| No. | Item | Specification | Note | |||||||||||||||||||

| Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||||||||||

| 1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

| |||||||||

| 2 | Thickness mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | ||||||||||

| 3 | Width Variation % | -0.5 | ||||||||||||||||||||

| 4 | Breaking Strength KN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14 | 16 | 19 | 25.0 | MD and CD | |||||||||

| 5 | Elongation at Break % | 25 ~ 100 | ||||||||||||||||||||

| 6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

| |||||||||

| 7 | equivalent opening size 0(0)mm | 0.07 ~ 0.20 |

| |||||||||||||||||||

| 8 | Vertical Permeability Coefficient cm/s | k× (10-1 ~ 10-3) | k=1.0-9.9 | |||||||||||||||||||

| 9 | Tear Strength KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD and CD | |||||||||

| Needle punched geotextile after treatment method | ||||||||||||||||||||||

Advantages

1, high tensile strength

2, the corrosion resistance

3, good water permeability

4, anti-microbial

5, the material is soft and easy for construction.

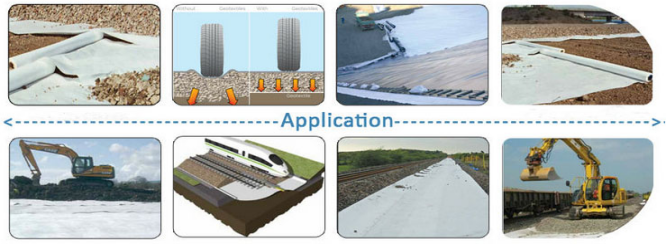

Applications

1, The product can be used to protect and reinforce soil and has the function of filtration, drainage in land reclamation.

2, water dams and protect drainage, filtration, homogenization base stress beam deformation of foundation prevent cushion clogging, to accelerate the consolidation drainage to improve the strength and stability of the foundation.

3. Reinforce slope Retaining Wall, to improve its stability.

4, dams, drainage software enhanced filtration and drainage.

Product Categories : Geotextile Materials > Geotextiles