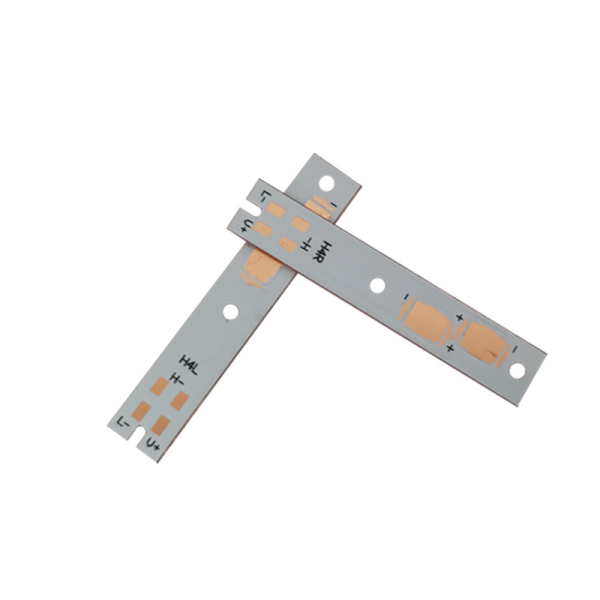

Xpc copper clad laminated sheet PCB

- Packaging:

- Vacuum packing

Basic Info

Model No.: pcb xpc pcba

Product Description

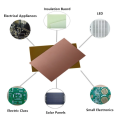

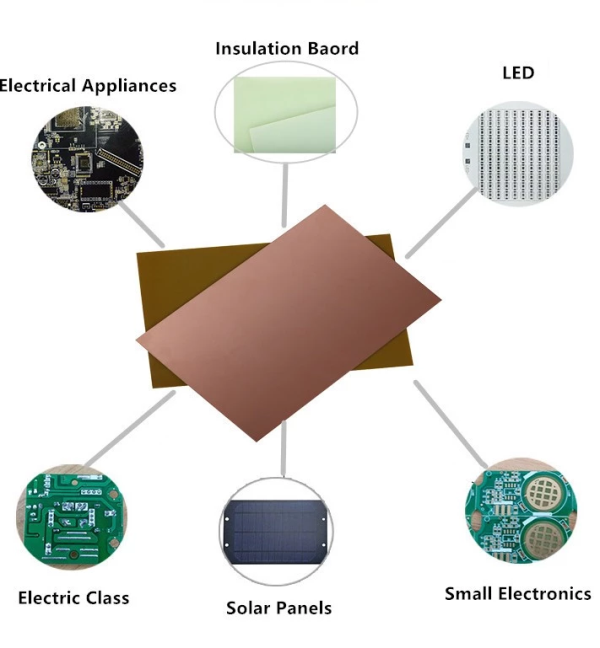

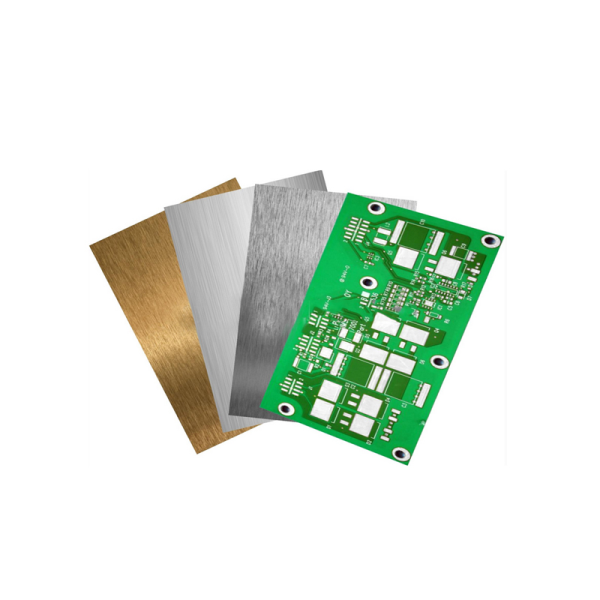

What is flexible copper clad laminate? Flexible Copper Clad Laminate (FCCL) is the base material of Custom Flexible PCB fabrication that appeared in the 1970s. It is composed of metal foil (usually copper foil), insulating film, and adhesive. Different materials and different functional layers are compounded and can be bent and flexed as a printed board substrate. Custom Flexible PCB fabrication has developed rapidly in recent years, and its output is close to that of rigid printed boards, and is widely used in portable communication equipment, computers, printers and other fields.

In order to reduce the thickness of flexible printed boards, improve flexibility, heat resistance and peel resistance, and achieve the needs of high performance and thinner printed boards, two-layer FCCL has been developed in recent years. It does not require adhesives, and directly It is composed of flexible insulating material and copper foil. Since acrylic adhesive is not used, the thermal expansion coefficient of the substrate in the Z direction is small, and the dielectric loss during high-speed signal transmission is small. It is the preferred material for flexible substrates in rigid-flex printed boards to produce Rigid-Flex Board. However, the current supply of the substrate is not as large as that of the three-layer method substrate, and the cost is also high.

The main flexible boards are copper-clad polyester film, copper-clad polyimide film, copper-clad polyimide fluorocarbon vinyl film, and thin epoxy glass cloth copper-clad laminate (thin FR-4).

Copper-clad polyester film has good mechanical and electrical properties such as tensile strength, dielectric constant, insulation resistance, and has good moisture resistance and dimensional stability after moisture absorption. The disadvantage is poor heat resistance and large dimensional changes after heating. It is not resistant to welding, and the working temperature is low (less than 105°C). PET is only used for printed transmission lines that do not need welding and flat cables in electronic complete machines, etc.

Copper-clad polyimide film has good electrical properties, mechanical properties, flame resistance, chemical resistance, weather resistance, etc. The most prominent feature is high heat resistance, and its glass transition temperature Tg is higher than 220 ℃; The disadvantage is that the moisture absorption is relatively high, the size shrinkage rate is large at high temperature or after moisture absorption, and the cost is high. It needs to be pre-baked to remove moisture before installation and welding. PI is suitable for high-speed circuit microstrip or stripline-type signal transmission flexible printed circuit boards, and it is also the most widely used substrate among flexible substrates.

Thin epoxy glass cloth copper clad laminate is a kind of flexible substrate developed in recent years. In addition to flexural performance, in terms of insulation performance, moisture resistance, dimensional stability and other comprehensive properties, thin FR-4 board is significantly better than traditional FCCL , Has been applied to the carrier board of the tape IC package at present, and the cost is lower than the PI board.

These flexible substrates are divided into two-layer and three-layer flexible substrates according to the different manufacturing process methods. The difference between the two is: the three-layer method is a traditional manufacturing method, which is made of copper foil, insulating film and bonding The two-layer method is composed of insulating film and copper foil. There are several different manufacturing methods, but the common feature is that there is no adhesive. Compared with the flexible substrate of the three-layer method, the two-layer method has the advantages of thin thickness, light weight, better flexural performance and flame retardancy, easy impedance matching, and good dimensional stability. The two-layer flexible board is more suitable for high-speed circuit FPCs with impedance matching requirements, high-density wiring FPCs, as well as the carrier boards of Electronic Components such as COF, TBA, CSP, and the flexible part of the rigid-flex printed board.

Among the above two types of materials, they can also be classified into general base materials, base materials for high frequency boards, base materials for high frequency mixing pressure plates, high heat-resistant base materials, high dimensional stability, and environmentally friendly base materials. Materials and so on.

Product Categories : High Frequency Board > Ceramics Base Copper-clad Laminates